Adhesive Peel Tester exporting|peel testing system : retailer Peel testing is critical for evaluating the seal strength of various adhesive bonds. Some bonds, such as those that seal consumer packaging, are intended to be break at low forces, while others, such as those used in automotive . Resultado da Benzoderm (Benzoato De Benzila) é um medicamento Similar, Antiparasitários do laboratório Pharmascience: bula, para que serve, como .

{plog:ftitle_list}

WEBSonic Mania is an all-new adventure with Sonic, Tails, and Knuckles full of unique bosses, rolling 2D landscapes, and fun classic gameplay. Recent Reviews: Overwhelmingly Positive (148) All Reviews: Very Positive .

ASTM D3330 Test Methods. ASTM D3330 includes six distinct test methods (A-F) to evaluate different types of peel adhesion. Here’s an overview: Method A – Measures 180° peel .Peel testing is critical for evaluating the seal strength of various adhesive bonds. Some bonds, such as those that seal consumer packaging, are intended to be break at low forces, while others, such as those used in automotive . Peeling takes a wide array of forms. In the most basic sense, a peel test can consist of (1) a laminate comprising of two (or more) layers peeled apart, often at the interface or (2) an adhesively bonded joint in which two substrates are joined by an adhesive layer and then peeled apart, or (3) peeling of a single, adhesive material from a substrate or itself.Test Procedure: Clamp each ends of the t-peel specimen in separate test grips of the universal tester / tension testing machine. Separate the specimen at a rate of 127 mm (5.0 in) /min for (5-in.) length of the bond line. Specimen size: Specimens are cut from a T-peel panel to 25.4 mm (1.0 in) long x 300 mm (12 in) wide. Ten specimens are .

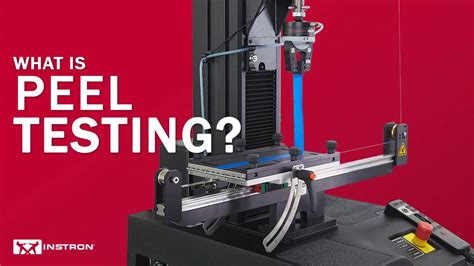

A peel test is a basic form of mechanical testing that measures the properties of an adhesive bond. Peel tests involve applying a tensile force to a flexible substrate that is bound by an adhesive to either another flexible substrate .

ASTM D3330 is a major peel testing standard that outlines the requirements for determining the peel adhesion properties of pressure-sensitive tapes such as surgical, electrical, packing, and duct tape. The standard includes 6 different methods (A-F) for measuring peel adhesion with both 90° and 180° peel tests.ADMET’s easy-to-use adhesive peel fixtures are employed by the adhesive industry to test the peel strength, bonding, and shear properties of adhesives. Peel fixtures conform to testing standards such as ASTM D1781, ASTM D3330, ASTM D3167 and can also be customized based on your test application. Below we will explore the types of peel tests .Lab Master® Release & Adhesion Tester. 80-91 - Testing Machines, Inc. (TMI). The Lab Master® Peel Tester for Release and Adhesion testing operates with Windows®-based software, and features the ability to create user-defined test set-up, individual test speed selection, user-definable default areas for analysis, exporting of graphs or data to Microsoft .

Module Adhesion Testing. . Test package for peel tester includes the motorized test stand with integrated digital force gauge, AC adapter/charger for 115VAC or 220VAC, data acquisition and exporting software, scoring fixture, ISO peel fixture, CQM angled fixture, stabilizing plates with rails, stabilizing plates for use with double-faced tape .

The 180-degree peel adhesion test measures the force required to peel a flexible adhesive from a solid substrate at an angle of 180 degrees. What is peel adhesion strength? Peel adhesion strength refers to the force required to separate an adhesive bond by peeling.ASTM D903 is a common tensile test used to evaluate the peel or stripping characteristics of adhesively bonded materials used in a wide variety of applications in an even wider range of industries. Some examples of materials tested to ASTM D903 are plastic films, adhesive labels, and waterproofing materials.This test method is specified by the ISO 11343 standard. The specific setup for the adhesive peel impact test consists of a wedge with a defined shape and mass, being driven at a defined velocity into an adhesive bond securing two metallic surfaces. The test causes the bond to fracture and the adherents to peel apart.ASTM D1876 measures the comparative peel properties of adhesive bonds between flexible adherends by using a T-peel test. The test is referred to as a “T-peel” due to the shape the two flexible adherends form as they are pulled apart. Average peel strength for each specimen type and average, minimum, and maximum peeling loads for each individual specimen are the .

Get precision measurements for 90° peel tests with the ChemInstruments 90° peel adhesive testing machine. The 90° peel adhesive tester runs at varying speeds for added flexibility and offers a number of additional features. . and low measured force results immediately upon completion of a test; Export data by USB connection to a local PC .According to ASTM D3330, specimens for the peel test must be prepared from pressure-sensitive tape of a specific size in order to measure the peel adhesion. The exact dimensions of the specimens vary according to the test method within the standard. In general, however, the specimens must be cut to meet the specified width and length requirements to ensure .Our Solution. Automotive and adhesives suppliers commonly use ISO 11343 wedge-peel impact testing method to compare the relative effects of various product and process variables on impact performance. Instron has developed standard as well as .A peel test is a basic form of mechanical testing that measures the properties of an adhesive bond. Peel tests involve applying a tensile force to a flexible substrate that is bound by an adhesive to either another flexible substrate (such as tape, thin film, or rubber) or a rigid substrate (such as metal, rigid plastic, or composite).

The data we provide assists material engineers in the selection of materials in global markets. It includes adhesive strength testing such as tensile, shear, and peel data, as well as other adhesive property tests (e.g., impact, odor, and aging). Testing can be performed in hot/wet/dry conditions at ambient, elevated, or reduced temperatures.

what is peel testing

peel testing system

Import & Export. Public Sector. Transportation Transportation. Aerospace. Automotive. Marine. Rail. Space. Products & Retail Products & Retail. Accessories. Appliances. Batteries. . Peel testing expertise for adhesives, coatings and laminates allowing accurate measurement of peel strength, coating durability and adhesive performance .

There are many test methods used to determine the strength of an adhesive including peel, shear, cleavage, and tension tests. Peel tests are common for tapes, labels, coatings, and other bonded materials. There are three main types of peel tests including 90 degree peel test, 180 degree peel test, and a T-Peel test. The Loop

For Outside India (Export Model) : As per your country’s power rating. 2. Desktop / Laptop PC (Intel Core i3, 4gb RAM, Win10 OS, 1080p Monitor) or higher. . Equipment - Series APT – A Adhesive Peel Tester for Adhesive Test Applications. Loadcell 1 / 5 / 10 1 Kgf / 5 Kgf / 10 Kgf Software RS Regular software. (Not 21-CFR-11 compliant)

An adhesion tester measures the force required to detach a coating from a substrate. Often called a pull-off adhesion tester or peel tester, an adhesion tester applies a large amount of force to evaluate a coating's bond strength. When measuring peel force or adhesiveness, the nature of the substrate's surface plays a significant role. However .

A peel test is a fundamental mechanical test that measures the properties of an adhesive bond. Peel tests involve applying a tensile force to a flexible substrate that is bound by an adhesive to either another flexible substrate (such as tape, thin film, or rubber) or a rigid substrate (such as metal, rigid plastic, or composite).The bonded test pieces can also be exposed to potentially detrimental storage conditions such as extremes of heat, cold, artificial sunlight or immersion in product chemicals before testing for peel adhesion. Alternatively, the peel test can be made at high or low temperatures to simulate harsh product environments. 180° Peel Test: The most common test, peeling the substrate away from the adhesive at a 180-degree angle. Ideal for evaluating general bond strength. Ideal for evaluating general bond strength. 90° Peel Test: Similar to 180°, but with a 90-degree peel angle. It has been found that the adhesion strength measured by the peel test is a practical adhesion (an engineering strength per unit width) and does not represent the true interface adhesion strength. The measured value may represent a multiplication of the true interface adhesion and other work expended in the plastic deformation of the thin film.

The most versatile peel tester on the market, the ChemInstruments Adhesion/Release testing machine with digital display is designed to perform PSTC, ASTM, TLMI, FINAT, and AFERA adhesion and release testing procedures. . and low measured force results immediately upon completion of a test; Export data by USB connection to a local PC with our .ASTM D3330-- Standard Test Method for Peel Adhesion of Pressure Sensitive Tape ; ASTM D3654-- Standard Test Methods for Shear Adhesion of Pressure Sensitive Tapes ; ASTM D904 -- Standard Test Method fo rComparison of Bond Strength or Ply Adhesion of Similar Laminates Made from Flexible Materials ;

A wide range of adhesive properties can be measured by applying tensile or compression forces in a controlled manner. Figure 1. Single- and Twin-Column Materials Testing Machines Figure 2. Test Jig Showing 90. Peel Test on a Pressure-Sensitive Barcode Label Materials testing machines provide a powerful way of evaluating adhesive performance. A .

peel testing software

peel testing methods

Bokep Tante hijab perkosa berondong Bokep Online Streaming-Watch Bokep Tant No Category 00:13:15 hijab ngirim nenen ke ayang

Adhesive Peel Tester exporting|peel testing system